By: Sobia Kishwer

In the rapidly evolving landscape of automotive and manufacturing, BitSource Technologies stands as a beacon of innovation, leveraging cutting-edge technologies to reshape industry practices. This article explores the transformative impact of BitSource's services in the realms of virtual prototyping, remote equipment monitoring, and employee training, revolutionizing the way vehicles and machinery are developed, maintained, and operated.

Virtual Prototyping and Testing Accelerating Innovation in the Automotive Sector

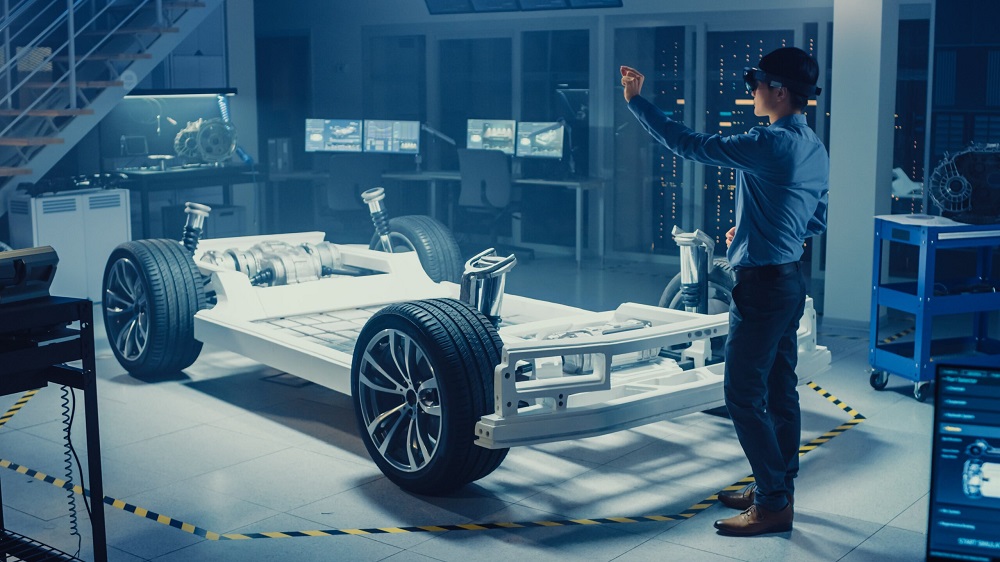

BitSource Technologies is spearheading a paradigm shift in the automotive industry by offering virtual prototyping and testing services. Traditionally, the process of designing and refining vehicles and machinery involves extensive physical prototypes, leading to prolonged development cycles and increased costs.BitSource's virtual solutions, however, enable manufacturers to create and test prototypes in a digital environment, significantly reducing time-to-market and expenses.

In the metaverse crafted by BitSource, engineers can simulate various scenarios, analyze performance metrics, and refine designs with unprecedented precision. This not only expedites the development process but also allows for rapid iteration and innovation. Manufacturers can now push the boundaries of design, ensuring that the final product meets the highest standards of safety, efficiency, and performance.

Remote Monitoring and Maintenance Enhancing Efficiency on the Factory Floor

BitSource Technologies introduces a game-changing approach to industrial equipment management with its remote monitoring and maintenance services. In the interconnected world of manufacturing, the ability to monitor equipment in real-time and perform maintenance tasks remotely is invaluable. BitSource's solutions empower manufacturers to proactively address issues, reduce downtime, and optimize operational efficiency. Through IoT (Internet of Things) integration and advanced sensor technologies, BitSource creates a virtual network that connects machinery and devices on the factory floor. This allows for continuous monitoring of equipment health, performance metrics, and potential failures. In case of anomalies, automated alerts are triggered, enabling timely intervention and preventing costly breakdowns. The result is a more reliable and efficient manufacturing process that minimizes disruptions and maximizes productivity.

Employee Training for Manufacturing Processes Bridging the Skills Gap

In the fast-paced world of manufacturing, employee training is crucial to ensure a skilled workforce capable of operating and maintaining complex machinery. BitSource Technologies addresses this challenge by providing immersive virtual training experiences that simulate real-world manufacturing processes. This not only enhances the skills of existing workers but also facilitates the onboarding of new talent. BitSource's virtual training modules allow employees to engage with machinery and production processes in a risk-free environment. From operating CNC machines to mastering assembly line procedures, workers can develop and hone their skills without the need for physical equipment. This not only accelerates the learning curve but also ensures that employees are well-prepared to handle the intricacies of modern manufacturing.

Conclusion: BitSource Technologies Paving the Way for a Digital Manufacturing Revolution

In conclusion, BitSource Technologies is at the forefront of ushering in a new era for the automotive and manufacturing industries. Through virtual prototyping, remote monitoring, and employee training, BitSource is transforming the way vehicles and machinery are conceived, operated, and maintained.

As manufacturing processes become increasingly complex, BitSource's services offer a holistic solution to streamline operations, enhance efficiency, and bridge the skills gap. By embracing the virtual realm, manufacturers can unlock new levels of innovation, resilience, and sustainability. BitSource Technologies is not just providing services; it's driving a digital manufacturing revolution that promises to reshape the future of automotive and manufacturing industries worldwide.